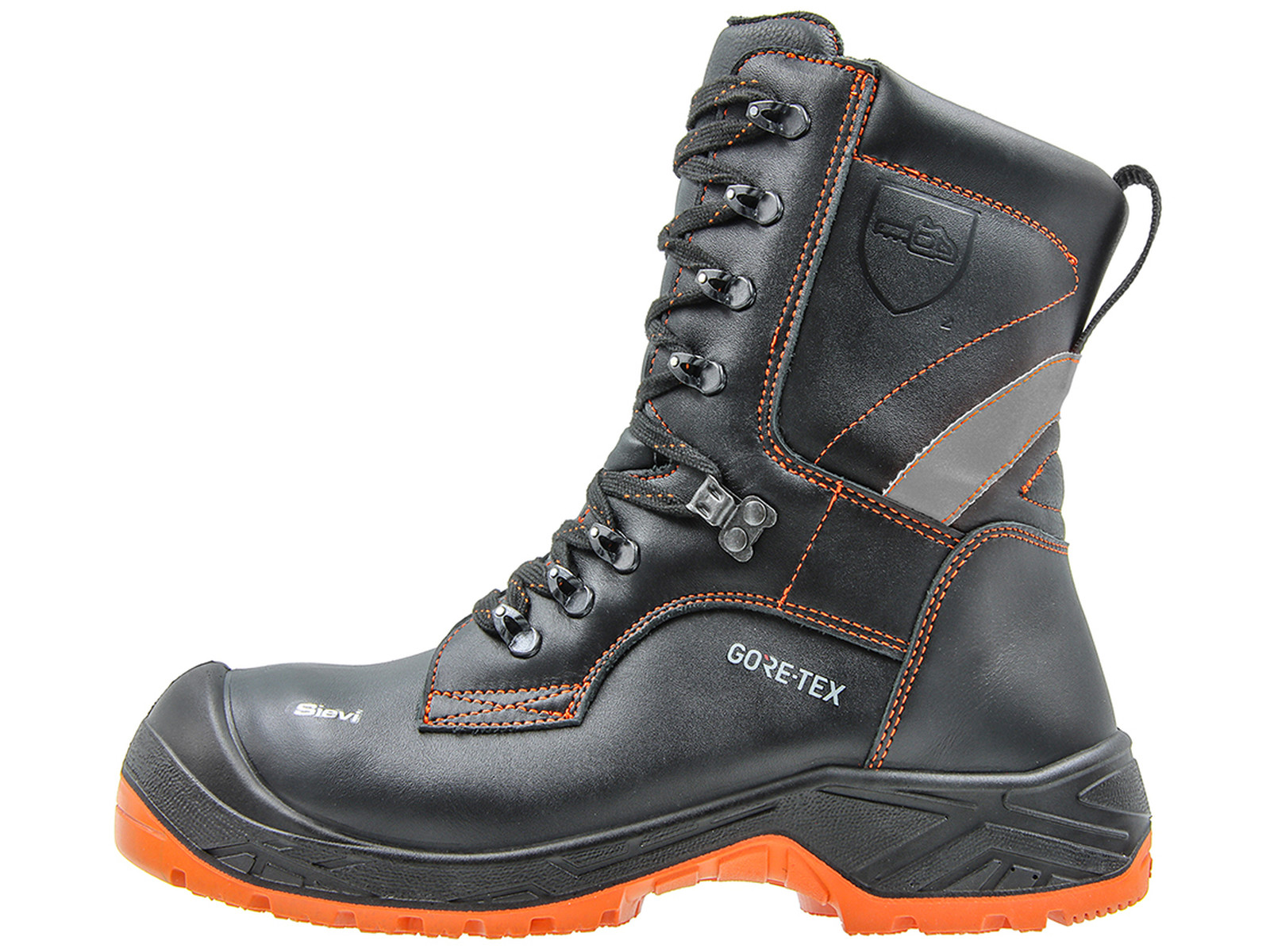

AL GT Timber XL+ S3 HRO

AL GT Timber XL+ S3 HRO

EN ISO 17249:2013 Level 2

AL GT Timber is a cut-resistant safety shoe for chainsaw users. The fit is wider than the standard fit, and the boot has shock-absorbing memory foam ankle padding. The breathable GORE-TEX layer ensures that the feet stay dry come rain or shine. The new profile of the rubber friction sole provides excellent grip on slippery surfaces and withstands temperatures up to 300°C. The foot is protected by steel nail penetration protection and aluminium toe cap.

Aluminium

The toecap protects toes from falling objects and compression. Meets the requirements of the EN ISO 20345:2022 standard: shock resistance is 200 J and resistance to compression 15 000 N. The aluminium toe cap is 50 % lighter than conventional steel toecaps.

Steel

The steel midsole prevents sharp objects from penetrating the sole. Meets the requirements of the EN ISO 20345:2022 standard: resistance to nail penetration is 1100 N.

Resistance to oil and many chemicals

The footwear sole resists oil and many chemicals. The oil resistance of Sievi footwear meets the requirements of the EN ISO 20345:2022 standard.

Antistatic

Antistatic footwear releases in a controlled manner static electricity accumulated in the body. The resistance limits are 100 kΩ - 1000 MΩ.

Water repellent

The upper material used in this footwear is water repellent. Its water resistance meets the requirements of the EN ISO 20345:2022 standard.

Shock-absorbing heel

Shock-absorption of the heel is a requirement of EN ISO 20345:2022 and EN ISO 20347:2022 standards: the shock absorption of the footwear must be at least 20 J. In all Sievi footwear the cushioning effect is guaranteed by the use of FlexStep® sole material, see FlexStep® for more information.

Heat resistance

The footwear can be worn in hot environments. Sievi’s nitrile rubber sole withstands temperatures up to 300 °C.

Double density PU/RU

The footwear sole consists of polyurethane and rubber. The PU/rubber friction sole features excellent grip and wear resistant properties. The mid-layer of the sole is made of shock absorbing FlexStep® material. Heat resistant up to 300°C.

XL-last

Sievi XL ranges. These extra wide styles offer more space and comfort for the wearer. For footwear with XL width fittings see “XL” in the product name.

Sievi Green Comfort

Recycled materials account for 67% of the total weight of the materials used in the insole. The surface material is polyamide, which is incredibly wear resistant and wicks moisture from the feet to the lower layer of the insole. The insole is antibacterial and odourless. The heel design keeps the foot’s fat pad in an optimal position, and the insole conforms to the shape of the foot and rebounds to its original shape when the footwear is taken off. Antistatic and machine washable at 40°C.

Ankle protection

The ankle has PORON XRD® support (Lazer Roller High+) or viscoelastic memory foam that moulds itself to the wearer's foot, supporting the ankle and absorbing shocks.

GORE-TEX

GORE-TEX lining is a unique waterproof lining material that allows the feet to breathe while keeping the moisture out of the footwear. This is the only membrane structure on the market systematically tested for its functionality and comfort.

Firefighters Boots

The fireman symbol ensures that the boots fulfill the requirements of the fire footwear standard EN 15090:2012: F1 P A.

Chainsaw protection

These shoes protect the user against chainsaw cuts and meet the Class 2 requirements of the EN ISO 17249:2013 standard for safety footwear with resistance to chainsaw cutting.

FlexStep®

The microporous FlexStep® sole material developed by Sievi maintains its excellent shock absorption and flexibility in freezing conditions. The structure of the FlexStep®flexible sole prevents strain on the feet and spine and absorbs shocks. The FlexStep® sole is used in all PU-soled Sievi footwear.

-

SizeProductGTIN

-

3948-52813-373-71M6438157182814

-

4048-52813-373-71M6438157182821

-

4148-52813-373-71M6438157182838

-

4248-52813-373-71M6438157182845

-

4348-52813-373-71M6438157182852

-

4448-52813-373-71M6438157182869

-

4548-52813-373-71M6438157182876

-

4648-52813-373-71M6438157182883

-

4748-52813-373-71M6438157182890

-

4848-52813-373-71M6438157182906