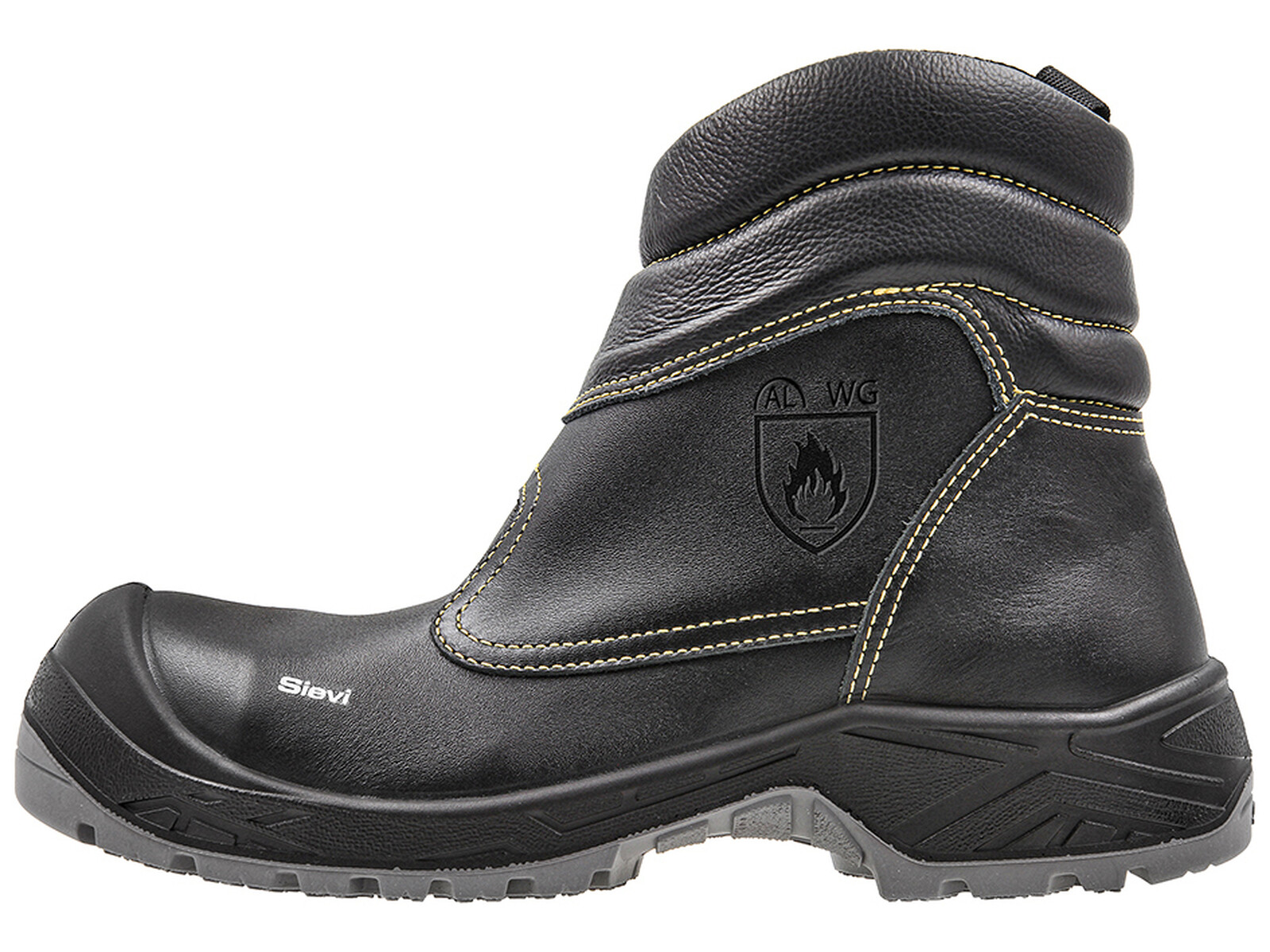

AL Hit Weld XL+ S3HRO

AL Hit Weld XL+ S3HRO

AL Hit Weld is a good choice particularly for welding work: the heat-resistant sole withstands temperatures up to 300°C and the stitching is in heat-resistant Kevlar. The FlexEnergy® heel component, the world’s most advanced shock-absorbing heel, gives 55% energy return. The product meets the requirements of standard EN ISO 20349-2:2017, footwear protecting users against the heat risks and molten metal splashes occurring in welding work.

Aluminium

The toecap protects toes from falling objects and compression. Meets the requirements of the EN ISO 20345:2022 standard: shock resistance is 200 J and resistance to compression 15 000 N. The aluminium toe cap is 50 % lighter than conventional steel toecaps.

Steel

The steel midsole prevents sharp objects from penetrating the sole. Meets the requirements of the EN ISO 20345:2022 standard: resistance to nail penetration is 1100 N.

Resistance to oil and many chemicals

The footwear sole resists oil and many chemicals. The oil resistance of Sievi footwear meets the requirements of the EN ISO 20345:2022 standard.

Antistatic

Antistatic footwear releases in a controlled manner static electricity accumulated in the body. The resistance limits are 100 kΩ - 1000 MΩ.

Water repellent

The upper material used in this footwear is water repellent. Its water resistance meets the requirements of the EN ISO 20345:2022 standard.

Shock-absorbing heel

Shock-absorption of the heel is a requirement of EN ISO 20345:2022 and EN ISO 20347:2022 standards: the shock absorption of the footwear must be at least 20 J.

Heat resistance

The footwear can be worn in hot environments. Sievi’s nitrile rubber sole withstands temperatures up to 300 °C.

Double density PU/RU

The footwear sole consists of polyurethane and rubber. The PU/rubber friction sole features excellent grip and wear resistant properties. The mid-layer of the sole is made of shock absorbing FlexStep® material. Heat resistant up to 300°C.

XL-last

Sievi XL ranges. These extra wide styles offer more space and comfort for the wearer. For footwear with XL width fittings see “XL” in the product name.

DUAL Comfort insole

The insole consists of three layers: a soft surface material, a breathable interlayer and a lightweight, shock-absorbing EVA bottom layer. On the heel and under the ball of the foot there

is a PORON® shock absorbing cushion, which absorbs external shocks and reduces strain.

ESD

Through its sole construction, ESD footwear provides a safe and controlled method of discharging the body’s static electricity. The resistance limits 100 kΩ - 35 MΩ for the Sievi ESD footwear are stricter than for antistatic footwear (IEC 61340-5-1). Wearing ESD footwear can help you avoid damage to sensitive electronic equipment.

Footwear for welding work

The flame symbol indicates that the footwear meets the requirements of the welding standard EN ISO 20349-2:2017 and protects against heat and splashes of molten metal.

3D-dry®

The 3D-dry® lining, developed by Sievi, transfers moisture away from the foot to the second layer of the lining material and further through the upper and away from the footwear.

FlexEnergy

The flexible FlexEnergy® component is integrated in the entire heel part of the shoe and provides maximum shock absorption of kinetic energy, with more than 55 % of the energy returned to you. The component is made of BASF’s TPU Infinergy® material, the world’s first expanded thermoplastic polyurethane.

The Key Flag Symbol

The Key Flag Symbol indicates that the product was made in Finland. The Sievi and Oulainen plants manufacture leisure footwear as well as safety and occupational footwear that have been awarded the Key Flag Symbol.

-

SizeProductGTIN

-

3948-52477-393-71M6438157212153

-

4048-52477-393-71M6438157212160

-

4148-52477-393-71M6438157212177

-

4248-52477-393-71M6438157212184

-

4348-52477-393-71M6438157212191

-

4448-52477-393-71M6438157212207

-

4548-52477-393-71M6438157212214

-

4648-52477-393-71M6438157212221

-

4748-52477-393-71M6438157212238

-

4848-52477-393-71M6438157212245